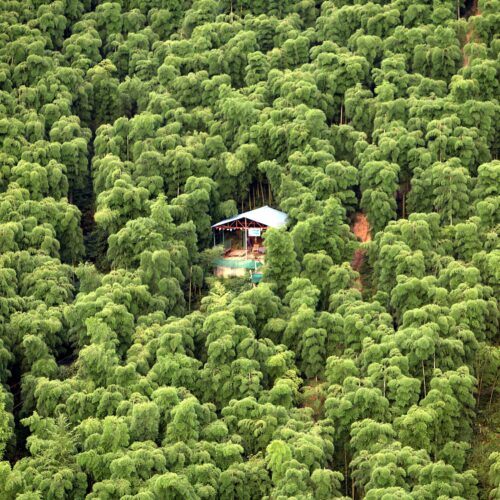

Sustainable production of bamboo at MOSO®

A sustainable production of bamboo at MOSO is something that we are...

After 4-5 years the bamboo stems are ready for harvest. This is very fast compared to (tropical) hardwoods and one of the main reasons why bamboo is ecological. After harvesting the stems are split lengthwise to strips and the outer skin (bark) is removed. The untreated strips have a yellowish colour but can be lightly steamed, reducing the yellowish tone (Ecru) or more intensely steamed for a warm brown colour (Caramel).

After treating and drying, the strips are ready to be joined in several ways to make the final product.

After drying the strips are assembled into the end product in various ways, resulting in the following versions (looks):

In the Plain Pressed version the bamboo strips are positioned horizontally and glued together. This creates an elegant line pattern with the characteristic bamboo nodes clearly visible.

In the Side Pressed version the bamboo strips are positioned vertically and glued together. This creates a narrow line pattern with the bamboo nodes visible in a subtle way.

Here the bamboo strips are crushed and then glued under extremely high pressure. This compression increases the density – from around 700 kg/m³ to more than 1000 kg/m³! – which makes the final product much harder. The look of High Density® bamboo is unique: it largely resembles wood with the typical “flames” with the bamboo nodes only slightly visible.

In this version the 7 or 15 mm wide bamboo strips are connected using a flexible fabric backing.

Bamboo’s original, natural colour is light brown with a yellowish tint. By treating bamboo with steam, the light brown colour becomes more intense and the yellow shade disappears, we call this Ecru. By increasing the temperature and pressure during the steam treatment, the durability and stability is enhanced and a warm brown colour appears, this is called Caramel. The colour Tiger was specially developed for panel materials: a mix of light and dark strips. By finishing with a stain lacquer or oil, even more bamboo product colours can be created. Ecru and Caramel products are only suitable for indoor use when further treatment is not undergone. Particularly in the case of outdoor products, the treatment is done at higher temperatures and with more pressure, which makes the bamboo dark brown, we call this colour Chocolate.

Are you considering bamboo and need some advice to discover which product is the best fit?

Don’t hesitate to get in touch with our MOSO® Bamboo experts.

René Zaal

Director of MOSO International B.V., the Netherlands

Discover more about MOSO® Bamboo Products and what makes bamboo the building material of the future in our extensive bamboo blogs!

A sustainable production of bamboo at MOSO is something that we are...

What is important to think about when looking at different decking types?

Discover everything about MOSO® Bamboo Products and why bamboo is the building...